الفئات

العلامات

الأرشيف

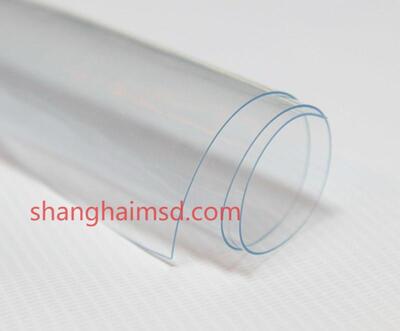

Shanghai MSD PVC Super Clear Film for Reliable Processing

-

نشرت من sean zhang - فشلت في أخرى - #MSD PVC Super Clear Film #PVC film #optical clarity #flexible film #industrial film - عرض٪ s

In manufacturing sectors where visual precision and material reliability are equally important, transparent films play a critical role in bridging aesthetics and performance. For many converters and end users, MSD PVC Super Clear Film represents a carefully engineered balance between optical clarity and processing stability, allowing transparent surfaces to remain visually consistent under real working conditions. As global demand for flexible transparent materials increases, attention has shifted from simple clarity toward long-term performance and controlled manufacturing outcomes.

The core material characteristics of PVC super clear film are shaped by resin purity and additive compatibility. High-quality PVC resin with low impurity levels forms the foundation of optical transparency, while advanced plasticizers contribute to softness and flexibility without introducing haze. Stabilizers are selected not only to protect the polymer structure during thermal processing but also to maintain color neutrality over time. Shanghai Ming Shida International Trading Company emphasizes material formulation stability, ensuring that the film performs consistently across different batches and application scenarios.

Processing precision is a decisive factor in achieving uniform transparency. During calendering or extrusion, even slight temperature fluctuations can affect melt flow behavior, leading to uneven thickness or optical distortion. Controlled cooling stages are essential to prevent internal stress buildup, which can later manifest as surface ripples or reduced clarity. Through refined process parameters and strict quality monitoring, manufacturers are able to produce super clear films with smooth surfaces and stable dimensional properties suitable for downstream fabrication.

Transparency alone is not sufficient if the film lacks mechanical reliability. PVC super clear film must maintain adequate tensile strength while remaining flexible enough for bending, folding, and repeated handling. These characteristics are achieved through balanced formulation design, where elasticity and strength are carefully aligned. The film’s resistance to tearing and puncture is particularly important in applications such as protective covers and flexible partitions, where physical contact is frequent. Consistent mechanical performance ensures that clarity does not come at the expense of durability.

In terms of applications, PVC super clear film is widely used in packaging, protective overlays, stationery, and household surface coverings. Its high transparency allows printed graphics, textures, or underlying materials to remain fully visible, making it ideal for display-oriented uses. In commercial interiors, the film serves as a protective layer for desks, shelves, and work surfaces, offering protection without altering visual design. Industrial environments also benefit from its ability to act as a transparent barrier against dust and light moisture exposure.

Testing protocols are essential for validating performance expectations. Optical testing focuses on haze values and light transmission rates to ensure visual consistency. Mechanical tests evaluate tensile strength, elongation, and tear resistance under controlled conditions. Surface performance is assessed through scratch resistance and anti-blocking tests, which are especially relevant during storage and transportation. Aging tests simulate prolonged exposure to heat and light, helping predict long-term behavior and appearance retention.

Surface feel and handling characteristics are often overlooked but play a crucial role in user satisfaction. A well-manufactured super clear film exhibits smooth touch properties without excessive tackiness. Anti-static and anti-blocking treatments may be applied to improve processing efficiency and reduce handling issues. Shanghai Ming Shida International Trading Company works with production partners to align surface performance with real-world usage, ensuring that the film remains easy to handle across different environments.

As market expectations evolve, PVC super clear film continues to adapt through improvements in formulation control and process optimization. Rather than focusing solely on appearance, manufacturers and distributors increasingly emphasize stability, testability, and application compatibility. For those seeking detailed insights into transparent film performance and industry trends, further information is available at https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .